The third biennial International Engine Building Forum (IEBF-2018, or MFD-2018 in Russian) took place at Moscow’s VDNKh fairground on 4th-6th April. The IEBF is billed as the world’s largest specialised event in the field of aero, marine and industrial engine design.

The IEBF is held under the auspices of Russia’s ‘Aero Engine Constructors Union’ Association (ASSAD) and the United Engine Corporation (UEC, or ODK in Russian). The UEC holding company, which is part of the Rostec State Corporation and controls more than 90% of Russia’s aero engine production, happens to be celebrating its tenth birthday this year and summing up what it has achieved in the past ten years, and this is one of the forum’s key themes. ‘Today the UEC is Russia’s largest machine-building corporation manufacturing high-tech products and making a sizeable contribution in such priority areas as aerospace industry development and national security, – says ODK General Director Aleksandr Artyukhov. – Our company relies on the extensive traditions of Russian aero engine design, preserving the unique legacy of the design schools of Vladimir Klimov, Pavel Solov’yov, Nikolay Kuznetsov and Arkhip Lyul’ka. We have the scientific, manufacturing and human resources to create next-generation engines in all areas where our holding company operates; we invest in new technologies and offer our advanced products on the world market. I am confident that our products will serve commercial and military operators well, promoting the production of Russian aero engines.’

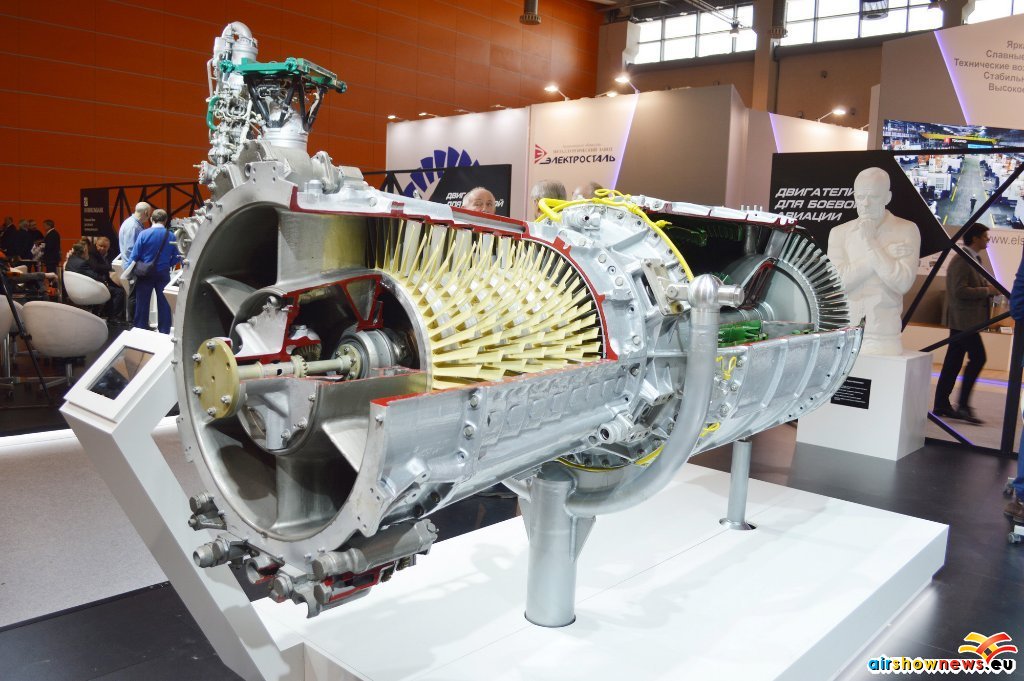

Speaking of Arkhip Lyul’ka (1918-1984), this year the Russian aerospace community celebrates his 100th anniversary. As a tribute, the UEC’s military powerplants line-up at IEBF-2018 included a cutaway example of the TR-1 turbojet of 1946, his first engine to reach the hardware stage and fly. Right alongside were some of the Lyul’ka-Saturn company’s latest products – the AL-41F-1S thrust-vectoring afterburning turbofan, which powers the Sukhoi Su-35S Generation 4++ fighter, and the well-known AL-31FN afterburning turbofan – now configured with an all-aspect vectoring nozzle for the latest version of the Chinese Chengdu Aircraft Corporation J-10 fighter. Also on display were the Klimov RD-33MK afterburning turbofan, which powers the Mikoyan MiG-29K/MiG-29KUB shipboard fighter and the MiG-35 Generation 4++ fighter, and the ZMKB AI-222-25 turbofan. The latter engine, which powers the Yakovlev Yak-130 advanced trainer, is now entirely produced in Russia; thus Russia no longer depends on the Ukraine, which has terminated all cooperation with Russia in military technology matters.

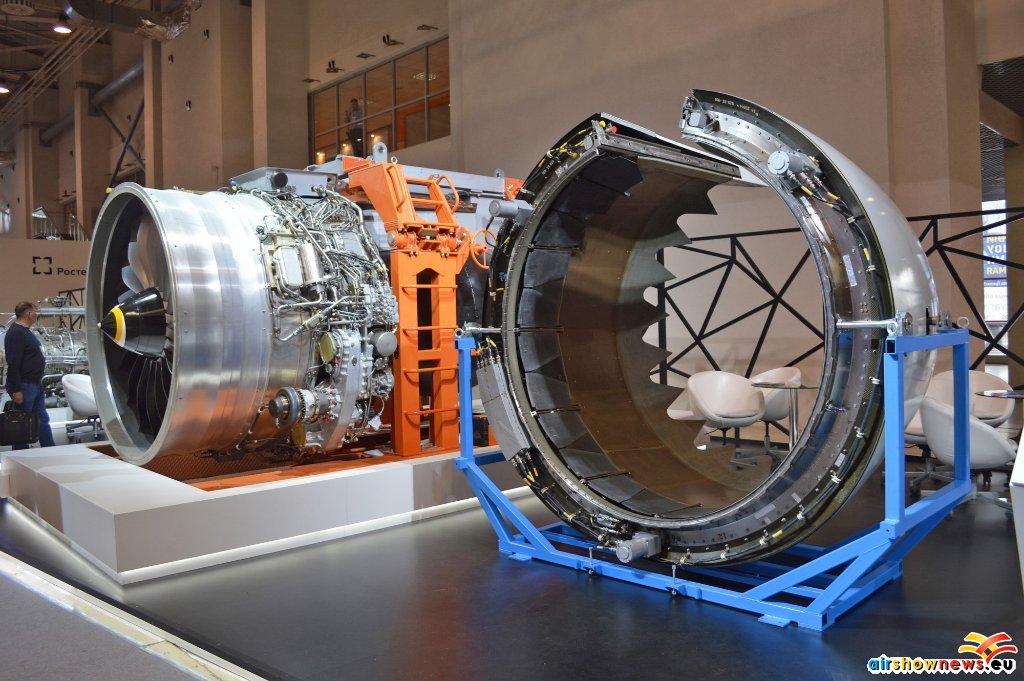

In the commercial range of UEC products seen at the forum, mention must be made of the Aviadvigatel’ PD-14 turbofan developed for the Russian MS-21 medium-haul airliner and of the Klimov VK-2500PS-03 turboshaft. The baseline PD-14 with a fan diameter of 1.9 m (roughly 6 ft 3 in) and a thrust of 14,000 kgp (30,865 lbst) is due to enter initial production this year. It is the progenitor of a whole family of both smaller and bigger engines, including the biggest and baddest 35,000-kgp (77,000-lbst) PD-35 high-bypass turbofan intended for the Sino-Russian CR929 wide-body airliner. Currently the PD-14 has fan blades of metal construction, but production engines may feature a new fan having carbonfibre reinforced plastic (CFRP) blades with a titanium sheath; a sample blade was shown at the forum. The UEC aims for certification of the engine in 2018, and tests on the MS-21 (which is currently powered by Pratt & Whitney PW1400G geared turbofans) will commence in 2019.

The VK-2500PS-03, which powers the recently certificated Mil’ Mi-171A2 medium utility helicopter, is the civil version of the VK-2500P engine fitted to the Mi-28N combat helicopter. It has full authority digital engine control (FADEC), a 2,500-shp take-off rating and a 2,800-shp contingency rating. However, NPO Klimov is already working on a next-generation helicopter engine. A production PowerJet SaM 146 turbofan – the Russo-French engine powering the well-known Sukhoi Superjet 100 airliner – was also on display.

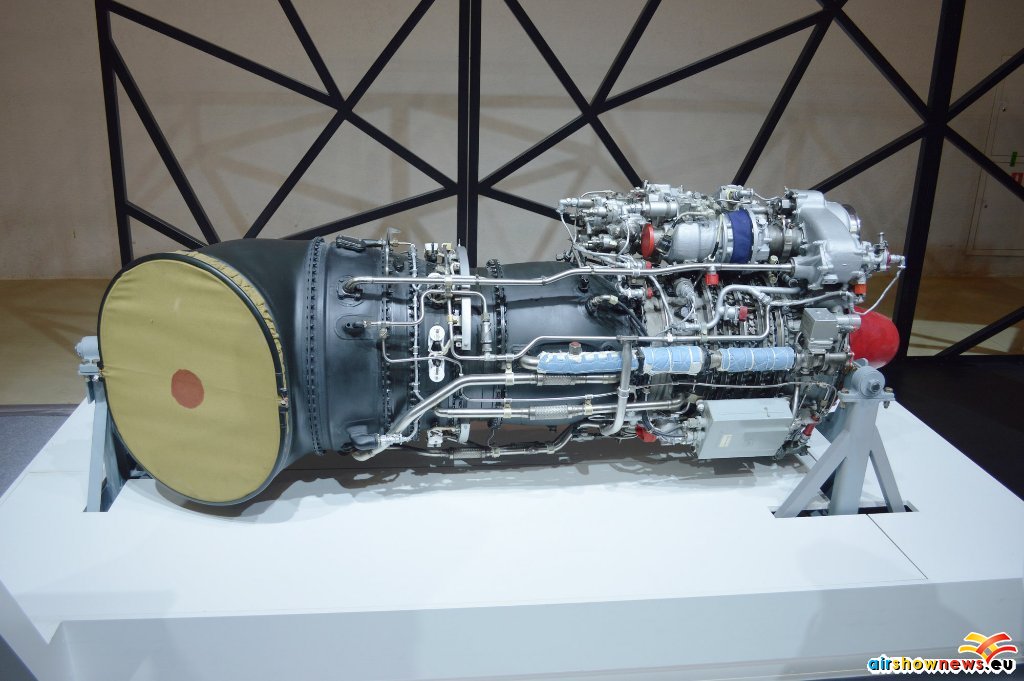

The main debut of IEBF-2018, however, is the Klimov TV7-117ST turboprop which was shown publicly for the first time. Starting life as a purely military uprated version of the TV7-117S for the Il’yushin Il-112V tactical airlifter, this is now also the powerplant for the rejuvenated Il-114-300 regional airliner. The engine has FADEC, a 2,900-ehp take-off rating and a 3,600-ehp contingency rating. The TV7-117ST first ran in September 2016 and commenced flight tests on an Il-76LL engine testbed a year later; as of now, it has completed initial flight tests and is awaiting clearance to fly in the actual Il-112V, which is due to enter flight test in the fourth quarter of 2018.

The Urals Civil Aviation Works (UZGA) located in Yekaterinburg presented another new turboprop. Originally developed as the 800-shp Klimov VK-800V turboshaft for light helicopters (vertolyotnyy – helicopter-specific), the engine has been making little headway since the early 2000s – chiefly for financial reasons. Now the uprated 900-ehp VK-800S turboprop (samolyotnyy – for fixed-wing aircraft) was shown in hardware form with a Czech-made Avia V-510 five-blade propeller. The engine is intended primarily for the Let L-410UVP-E20 feederliner which shoulders much of the air traffic in Russia’s outback areas. This is no matter of chance; the Let Kunovice factory producing the L-410 is now 100% Russian-owned but, with relations with the West going from bad to worse, the General Electric H80-200 turboprops for it may be embargoed at a moment’s notice if the USA gets the notion. Small wonder that the Russian industry wants to hedge its bets; the catchphrase of the day is ‘import substitution’!

…Blast from the past or powering the future? Nearly all of the full-size exhibits at the forum were dwarfed by a towering Kuznetsov NK-33 liquid-fuel rocket motor. This is a case of an intrinsically good design refusing to die in spite of the circumstances. The NK-33 had been developed in the early 1960s for the ill-fated N1 rocket that was to take Soviet cosmonauts to the Moon. While the man-to-the-Moon programme was cancelled after four unsuccessful launches, the NK-33 lived on; it currently powers the Soyuz-2-1B light space launch vehicle.

The stand of NPP Aerosila featured some of the company’s range of auxiliary power units (such as the TA-18-200 intended for the MS-21) and propellers. Apart from the now-familiar AV-112 six-blade propeller developed for the Il-112V, the visitors were treated to a first sight of the AV-115 two-blade prop developed for heavy unmanned aerial vehicles. An obvious application is the Kronshtadt Orion medium-altitude long-endurance (MALE) UAV which has been undergoing tests since 2016 and was unveiled last year at the MAKS-2107 airshow.

Light aircraft and UAVs were not left out either – also by ‘non-aligned’ engine manufacturers. The Agat Machinery Plant from the Russian town of Gavrilov Yam, which mostly manufactures non-aviation products, is attempting to diversify with a family of horizontally opposed petrol and diesel engines having two to six cylinders. The 120-hp Agat-B (APD-110/120) flat-four petrol engine was shown at the forum, as was a model of the MA-1 light aircraft being developed by an obscure Youth Design Bureau. This is to be a low-wing six-seater powered by a 300-hp Agat-D (APD-250/300) flat-six diesel. Estimated performance includes a take-off weight of 2,100 kg (4,630 lb), a payload of 590 kg (1,300 lb), a cruising speed of 300 km/h (186 mph), a range of 1,500 km (931 miles) and a required runway length of 800 m (2,620 ft).

One of the highlights at IEBF-2018 was provided by the Central Aero Engine Research Institute (TsIAM) which unveiled a concept of a hydrogen-powered aircraft. Actually there were two very different concepts; one is a scramjet engine running on hydrogen, which was presented in model form. The other is all about going green, not going fast: the aircraft is to be powered by electric motors fed by an electrochemical generator which runs on gaseous hydrogen. Unveiled in model form, the demonstrator will be based on the Russian Sigma-4 production two-seat light aircraft. The hydrogen tank and electrochemical generator occupy most of the space in the fuselage pod behind the side-by-side seats, while the electric motor and its power controller are housed in the engine nacelle above the wing leading edge, replacing the Rotax 912ULS piston engine. The TsIAM stand also featured a model of a turboelectric hybrid powerplant intended for propeller-driven regional aircraft, which is to utilise high-temperature superconductor technology.

Due attention was also given to technologies associated with aero engine deign and manufacturing. These included specialised metallurgy (represented by VSMPO-Avisma, a supplier of titanium and magnesium alloys, and the Elektrostal’ company supplying special-grade steels), instrument engineering, non-destructive testing and product support.